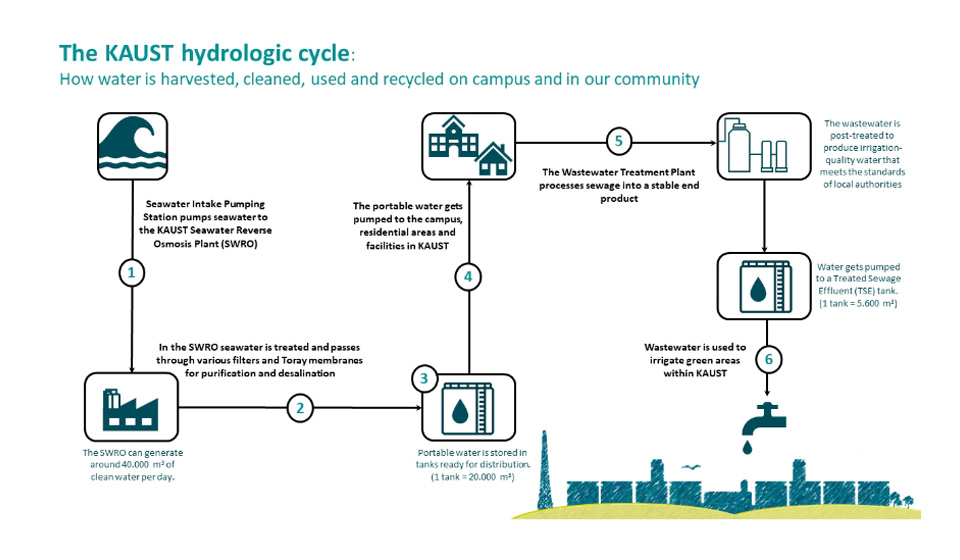

KAUST’s sustainability goals include a commitment to zero water waste, guided by a water management plan that calls for a reduction of the total on-campus consumption of potable water, including any loss from water distribution.

We produce all of our potable water from desalination, collect all of our wastewater for treatment, and reuse all of the resulting treated effluents in landscaping – completing a full water cycle in an effort toward resource circularity.

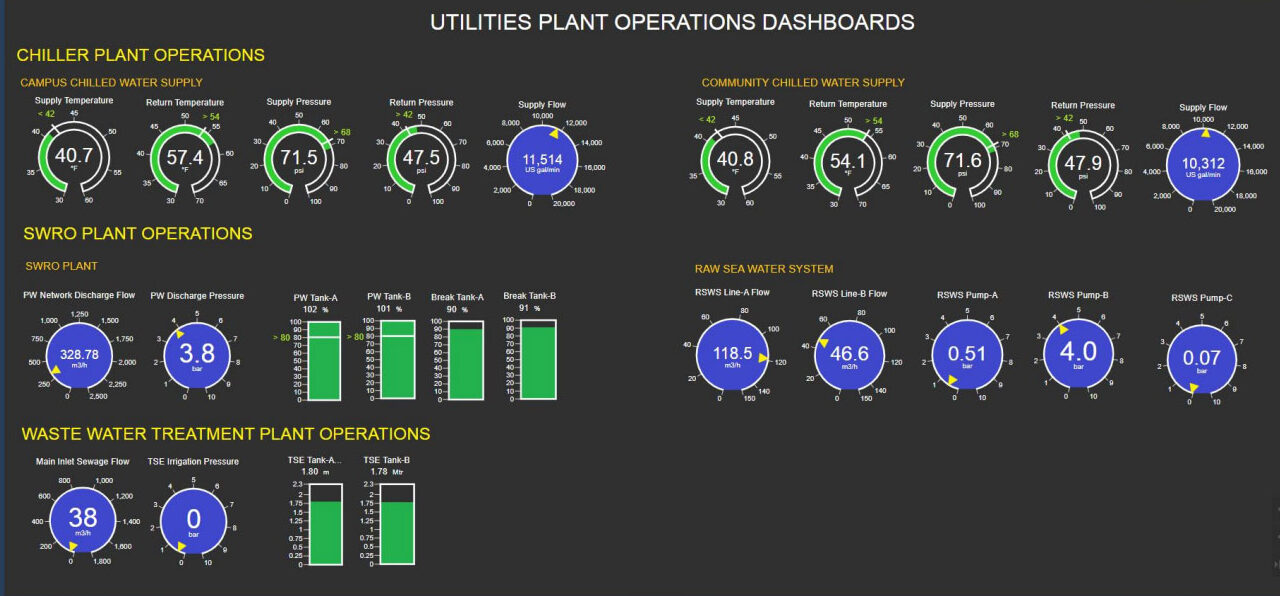

To ensure efficient management of this cycle, we rely on advanced monitoring systems, including the dashboards of the Central Utility Plant (CUP). These dashboards provide real-time monitoring and measurement of water consumption and production across our key facilities: the SWRO Plant, Wastewater Treatment Plant, and Chilled Water Plant.

With this technology, we optimize resource use, minimize waste, and uphold our commitment to sustainable water management.

KAUST WATER DESALINATION PLANT

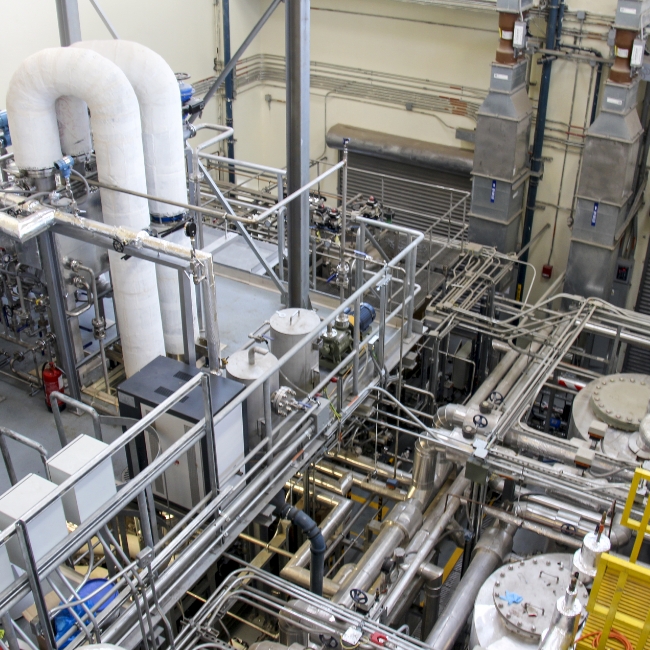

To provide the university and our community with potable water, KAUST owns and operates a Seawater Reverse Osmosis Desalination (SWRO) Plant with a 27,000 m3/day production capacity. This plant produces, monitors, and tracks all potable water provided to all consumers. The water it produces is routinely tested to ensure the highest quality and safety.

All operations related to water are controlled in centralized dashboards, ensuring all water that is produced and reused, is monitored and measured.

KAUST WASTEWATER TREATMENT PLANT

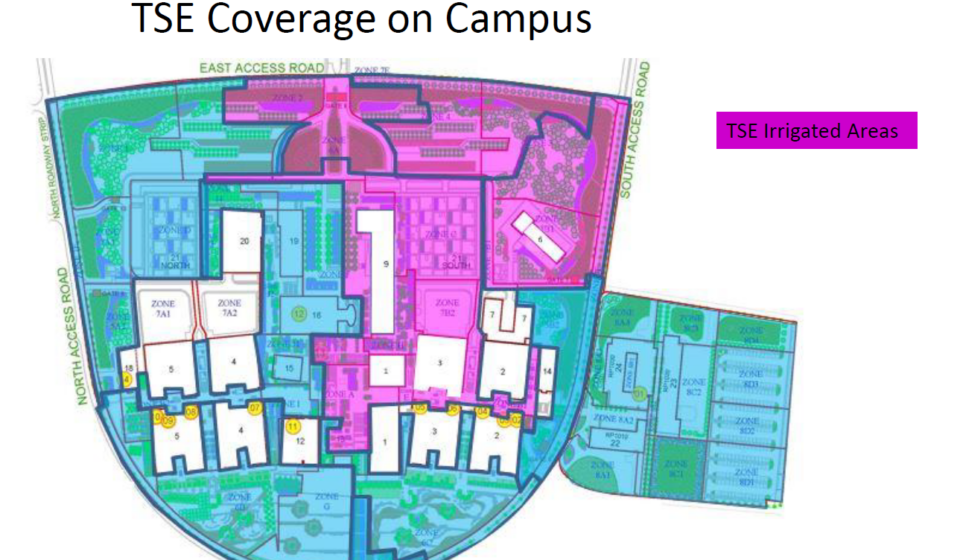

Our comprehensive water recycling system ensures all wastewater – including stormwater, grey-water, and black-water – from the campus and neighboring community is collected, treated, and reused at our local waste water treatment plant. This treated wastewater is repurposed primarily for irrigation across the University, reducing the demand for potable water. Our Wastewater Management Procedure, framed under an overarching Wastewater Code, ensures that all wastewater is effectively treated and reused, reflecting a systematic policy-level commitment to water conservation and recycling across our campus.

This state-of-the-art plant can treat 11,500 m³/day of effluent using membrane biological reactor technology. Our Treated Sewage Effluent (TSE) Water Use Protocol ensures that the produced TSE is measured and meets rigorous international standards guaranteeing high quality water for safe use. To achieve this, we test the effluents three times a day at an in-house laboratory and once every two weeks at an independent third-party laboratory. This careful testing process helps maintain consistent treated wastewater quality and ensures it meets safety standards.

The average amount of TSE produced annually by the plant is 1.6 million m³, with an average daily inlet effluent of 4,500 m³/ day.

KAUST is proud to reuse 100% of its treated waste water to irrigate green spaces across the academic campus and surrounding community. 35% of the total irrigation water used daily for all landscaping at KAUST comes from TSE, and so does 38% of the daily total irrigation water used for the academic campus.

KAUST CENTRAL CHILLED WATER PLANT

Given our local climate, KAUST operates a central chilled water plant designed to produce up to 45,000 tons of refrigerant (TR), with a future expansion capability of an additional 7,000 TR.

Through a 24 km-long network, chilled water is provided to campus buildings, residential apartments, facilities, and central service buildings. The plant is continuously monitored to ensure process optimization and energy efficiency.

WATER SYSTEM POLLUTION PREVENTION

KAUST also carries several actions to prevent water system pollution such as oil spill emergency drills or construction/renovation project reviews.

In addition, KAUST routinely tries to implement efficient and sustainable biological control measures in its water bodies.

WATER-SAVING ACTIONS

EQUIPMENT

All conventional water fixtures across KAUST have been replaced with water-saving devices, reducing water flow by 40% to 55%.

On campus, all faucets have been equipped with touchless automatic motion sensors, for minimal water waste.

Displacement tanks have been installed on all toilets, reducing the volume of water used for each discharge.

WATER REFILLING

STATIONS

To optimize access to drinking water on campus, we have installed free water refill stations (Elkay ezH2O ®️ bottle filling stations). These stations are located in every KAUST building, in the campus diner, and Community facilities, encouraging students, faculty, staff, community members and visitors to bring and use their own bottles, which cuts down on plastic and water waste. Additionally, there are dedicated water fountains for workers, visitors, and residents across our green areas.

WATER CONSCIOUS LANDSCAPING

To reduce daily irrigation needs, we have implemented xeriscaping design concepts across more than 100 sites on campus and in the surrounding residential community. Xeriscaping focuses on using rocks, and other materials to reduce or eliminate the need for irrigation while enhancing soil moisture retention. In addition to this, we utilize water conscious soil management techniques including mulching, improving the soil structure, and using compost (from KAUST’s local composting facility) to enhance our landscaping.

We also prioritize water-conscious planting, incorporating a diverse collection of over 144 plant species, of which 101 (70%) are drought-tolerant, making them well-suited to the region’s dry environment.

These efforts, combined with the conversion of parts of the potable irrigation network to treated sewage effluent (TSE), landscaping optimization, irrigation shut-off days, and residential backyard site improvements, have resulted in a 50% reduction in water used for irrigation since 2015.

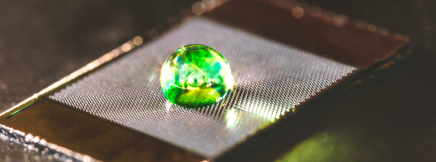

TESTING NEW SUSTAINABLE WATER EXTRACTION TECHNOLOGIES

KAUST is always exploring more sustainable desalination techniques at its Water Desalination and Reuse Center, where pilot-scale research facilities are used to scale up research ideas for potential commercialization. These pilot facilities (4 completed and operating, and 2 planned) focus on key areas of water sustainability, such as seawater desalination, solar adsorption, industrial water treatment, natural water treatment, and wastewater reuse.

Among these facilities is the Seawater Reverse Osmosis (SWRO) Pilot Facility, which tests energy-efficient membrane technologies to optimize desalination processes. The SWRO facility is designed for real-world applications, allowing researchers to trial innovative solutions that reduce energy use while ensuring the effective production of potable water from seawater. In addition, the Adsorption Desalination (AD) and Adsorption Desalination with Multi-Effect Distillation (AD-MED) Pilot Facility explores advanced adsorption technologies that harness solar energy to desalinate water, further minimizing environmental impact by integrating renewable energy into the water extraction process. For industrial water treatment, the Industrial Cooling Tower Pilot Facility supports research on sustainable cooling solutions that treat and reuse water in industrial processes, ensuring minimal water waste and enhancing resource efficiency in high-demand sectors.

Through these initiatives, KAUST not only meets its on-campus water needs but also contributes to the development of technologies that can be applied to off-campus communities and industries. By piloting these technologies, KAUST advances sustainable water extraction practices for arid regions like the Kingdom.